Experience Reliable Car Repair in Albuquerque, NM

At Rio Grande Automotive, we understand how important it is to have a mechanic you can trust. We’re not just an auto repair shop; we’re your neighbors, serving the Albuquerque community with integrity and reliability. We’re committed to providing top-notch, honest services that will keep your vehicle running smoothly. Our team values transparency and we’ll always keep you informed about what’s happening with your vehicle.

We know it’s not always easy to find a mechanic who truly cares about your vehicle as much as you do. That’s why we’re proud to be different. Here at Rio Grande Automotive, we treat every car that comes into our shop as if it were our own. We’ve built our reputation on reliability and honesty, and we’re dedicated to maintaining that standard. So, next time your car needs service or repair, remember – we’re here and ready to help, with integrity you can count on.

Understanding Vehicle Malfunction/Damage in Car Repair

We’re all familiar with the sinking feeling of having our car break down at the most inconvenient time. Whether it’s a flat tire on a deserted highway late at night, or an engine failure on the way to an important meeting, vehicle malfunction is an experience we’d all prefer to avoid. But understanding the common causes of car breakdowns and how to respond to them can make a world of difference.

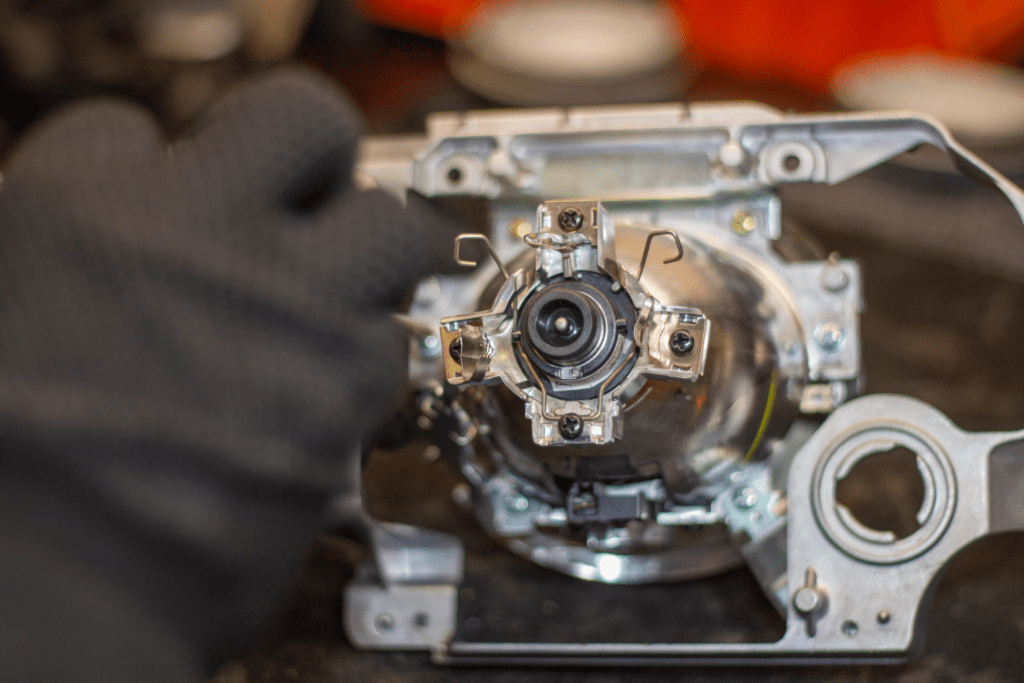

- Ignition System Failure: One of the most common causes of vehicle malfunction is a failure in the ignition system. This can be due to a variety of reasons, from a worn out ignition switch to problems with the starter motor. The signs are generally unmistakable – the car either doesn’t start at all, or it stutters and stalls when we try to fire it up. The best response in such a situation is to call for professional help. Attempting to fix an ignition system without the right tools or knowledge is a quick way to worsen the problem.

- Flat Tires: It’s surprising how many car breakdowns are caused by flat tires. We’ve all felt that sinking feeling when we hear the thud of a flat tire. The good news is, flat tires are one of the easiest vehicle malfunctions to fix. Armed with a spare tire, a jack, and a tire iron, we can usually have the car up and running in no time. However, it’s crucial to check tire pressure regularly and replace worn-out tires to avoid flats in the first place.

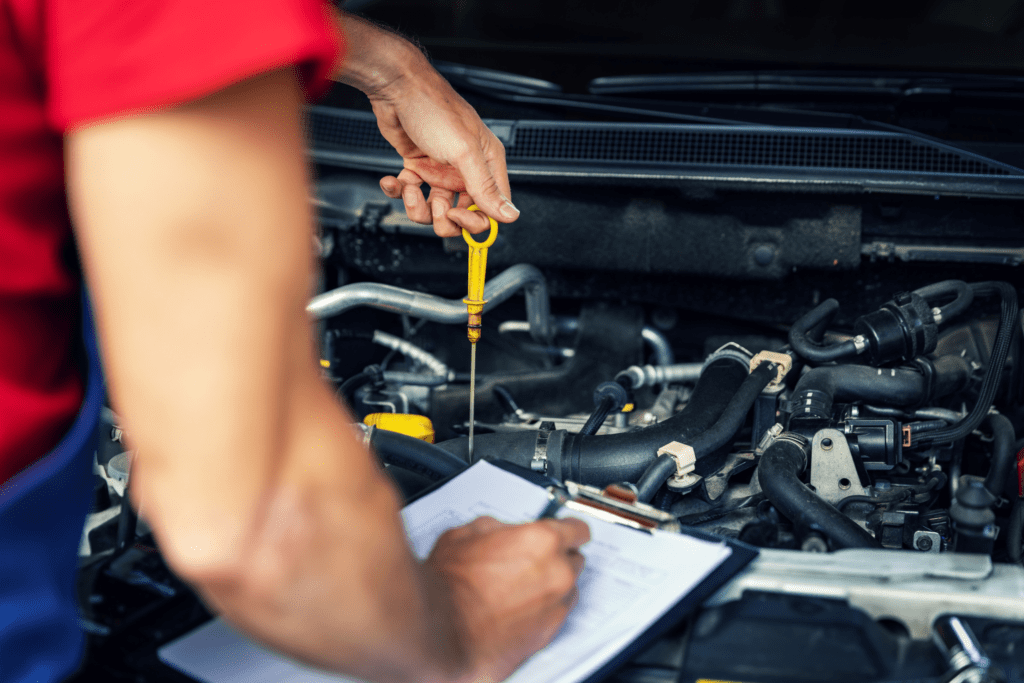

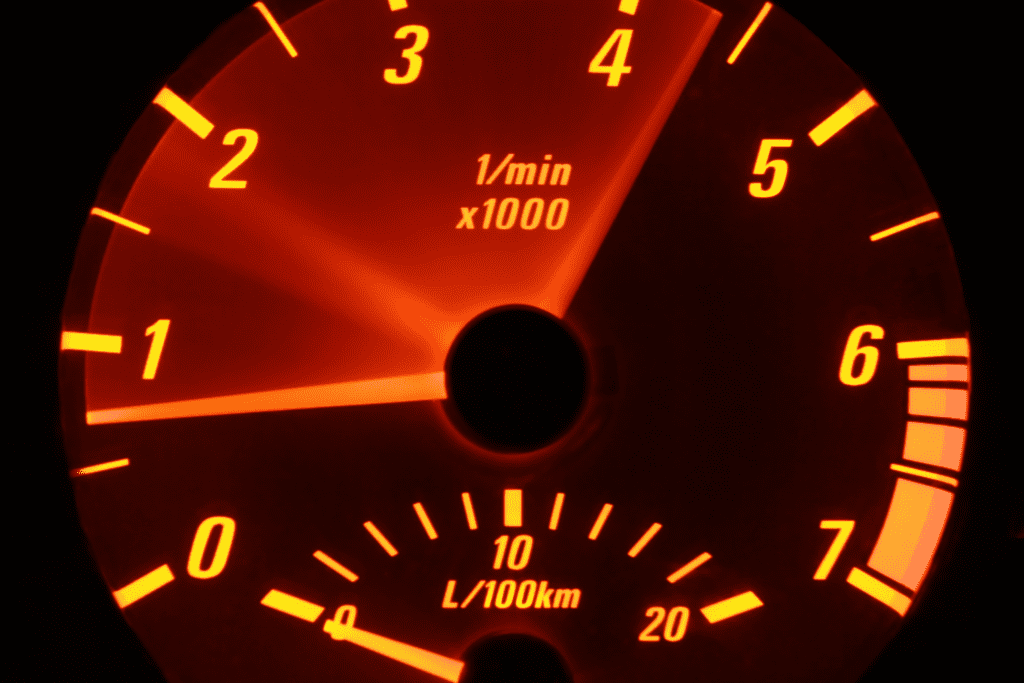

- Overheating Engine: Overheating engines are another common cause of vehicle breakdowns. This is usually due to a lack of coolant in the engine, a malfunctioning radiator, or a busted water pump. An overheating engine can cause serious damage to the car, and it’s crucial to pull over and let the engine cool down as soon as we notice the temperature gauge creeping up. Regular maintenance, including checking the coolant levels and ensuring the radiator is functioning properly, can help prevent engine overheating.

Nobody enjoys dealing with vehicle malfunction/damage, but understanding the common causes and knowing how to respond can help turn a potential disaster into a minor inconvenience. Regular maintenance and prompt professional help when needed are the keys to keeping our cars running smoothly and avoiding breakdowns.

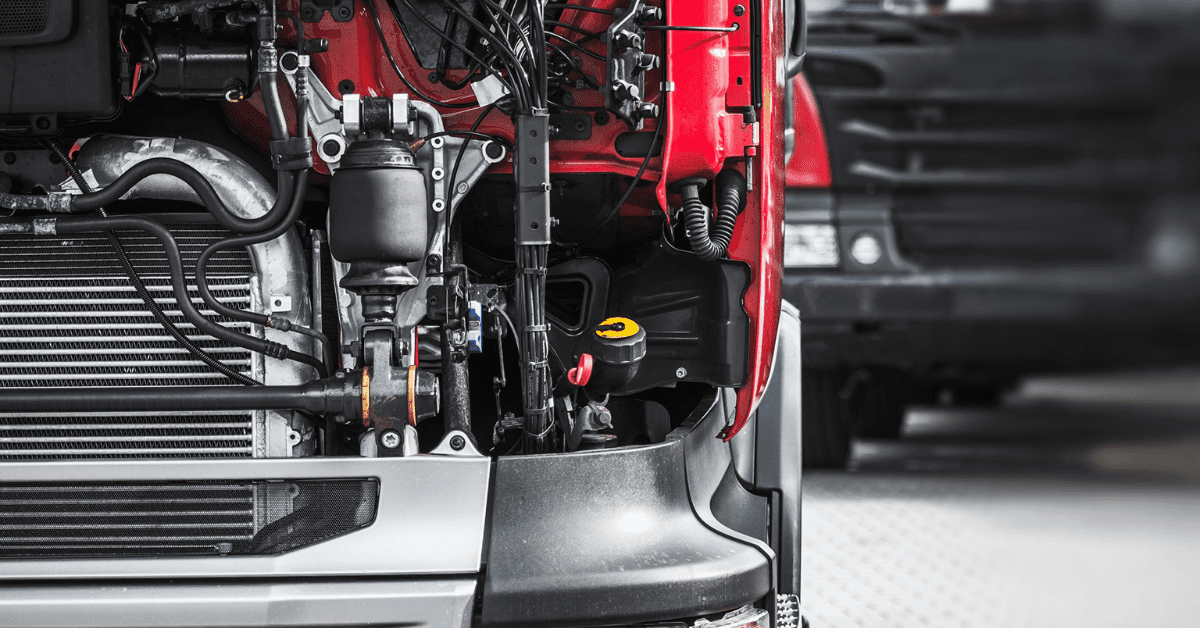

The Vital Role of Car Repair in Everyday Life

We can’t stress enough how essential car repair is to your daily life. As a society, we’re heavily reliant on our vehicles for commuting to work, dropping off the kids at school, or even for those much-anticipated road trips. When our cars run smoothly, it’s easy to take them for granted. But when something goes wrong, it can throw a wrench into our daily routines. That’s where we, at Rio Grande Automotive, come in.

We’ve been a family-owned and operated business since 2015, serving the Albuquerque, NM area with pride. We truly believe that routine maintenance and timely repairs can not only extend the lifespan of your vehicle but also ensure your safety on the road. Here are some key aspects of car repair that we handle:

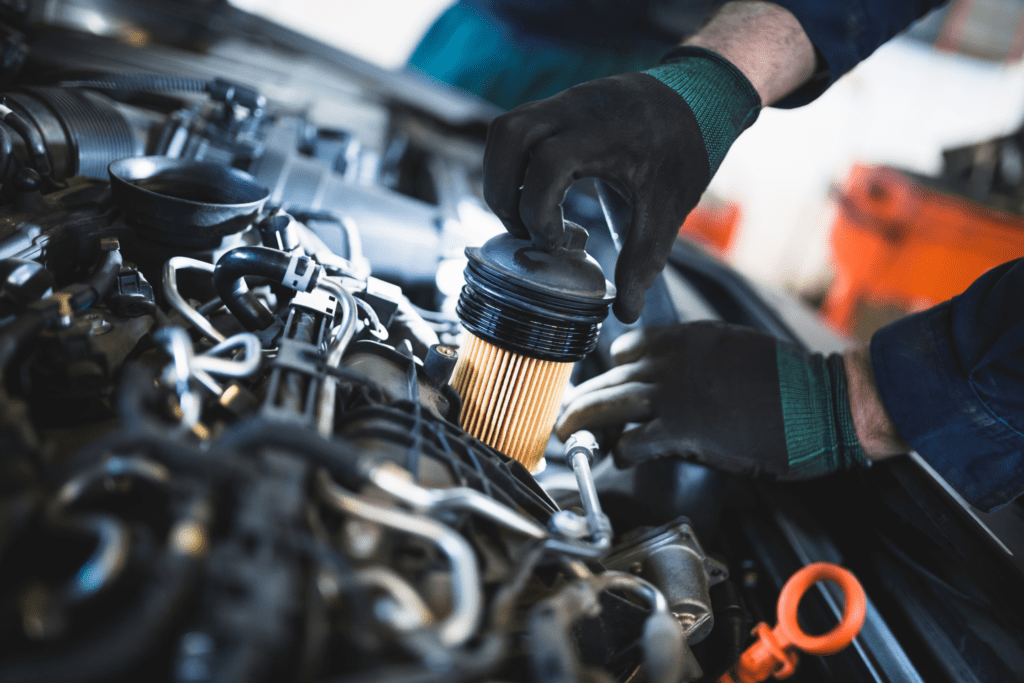

- Regular oil changes to keep your engine running smoothly

- Brake checks and repairs to ensure your safety

- Tire rotation and balance to improve vehicle handling

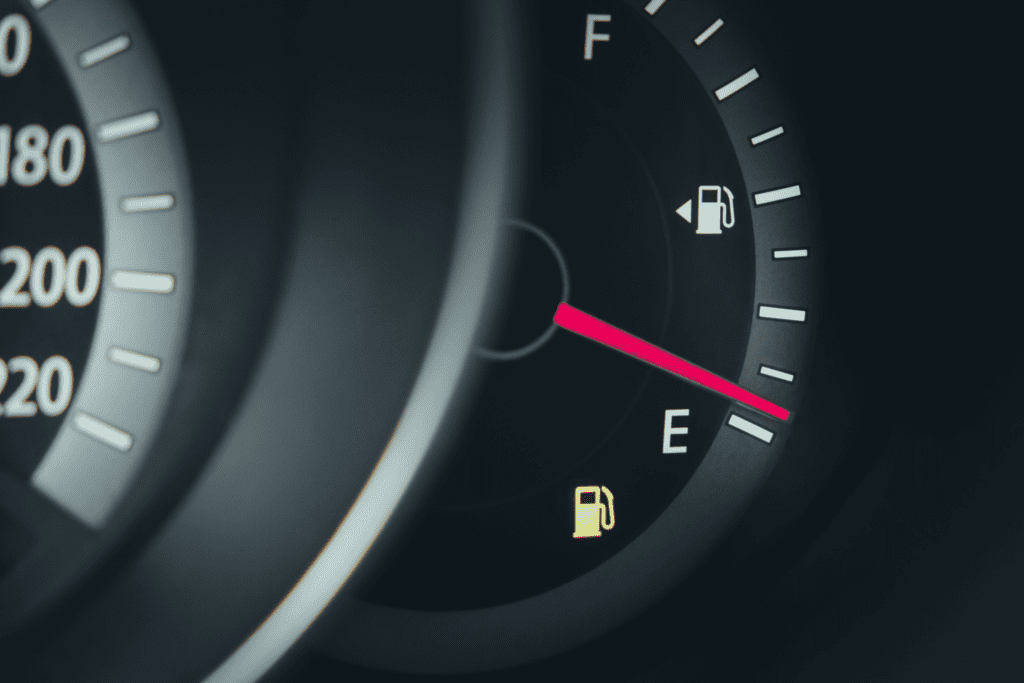

- Battery checks to avoid unexpected breakdowns

- Cooling system maintenance to prevent overheating

We understand how valuable your time is and how disruptive car issues can be. That’s why we’re committed to providing top-notch service, so you can get back on the road as quickly as possible. Trust us, your car is in safe hands with Rio Grande Automotive.

Why is Rio Grande Automotive’s Signature Car Repair Service the perfect fit for your vehicle needs?

Are you seeking an auto repair shop that not only fix your car problems but also take into account the uniqueness of your vehicle? At Rio Grande Automotive, we are all about precision and care in every detail. We understand that your car is not just a mode of transport; it’s an extension of your personality, and it deserves the best care possible.

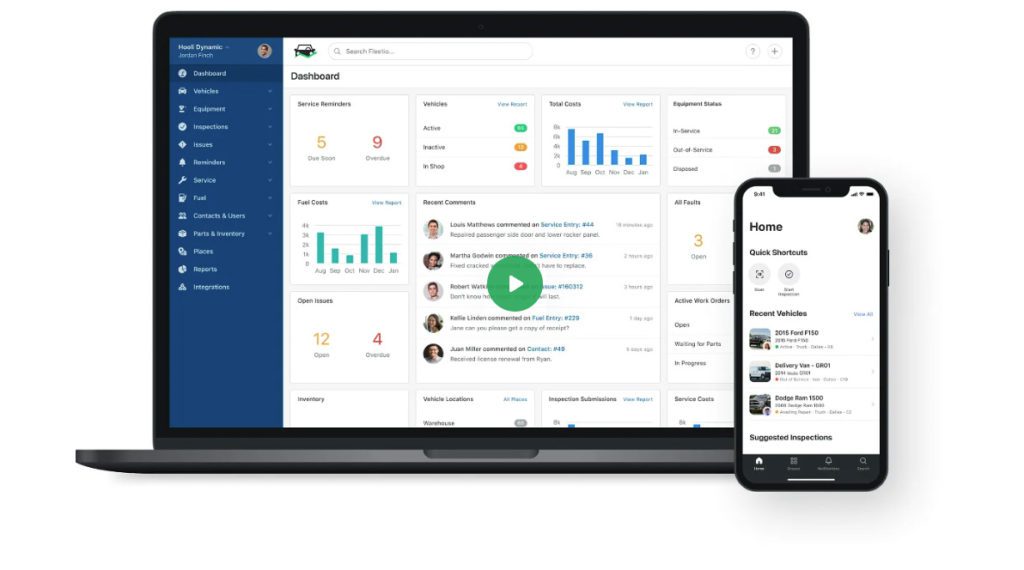

We’re not your regular mechanic shop. Our team employs masterful craftsmanship in every repair job we undertake. It’s not just about fixing the problem; we ensure that every detail is perfect and up to your standards. We’re also big on technology, utilizing cutting-edge diagnostics to accurately determine what’s wrong with your vehicle. This not only saves you time and money, but it also means we can address any underlying issues that might not be immediately apparent. Efficiency and timeliness are key to our service delivery because we understand how much you rely on your vehicle. You can trust us to always deliver top-notch, timely services.